3D Precast System

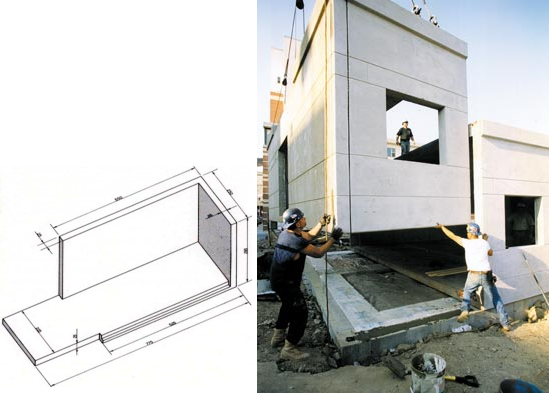

The 3D Precast System consists of three-dimensional elements (slabs and load-bearing walls together).

This system is mainly for residential buildings, it allows further completion steps into the factory plant (MEP, bathroom, furnishings, kitchens, floors and internal/external claddings).

So, a very important feature is the fast installation of the 3D elements.

We can start from the architectural, structural and MEP design, then the design of the factory plant follows. In this way the factory can be fully optimized on the scope of the work.

The 3D Precast System provides the breakdown of the building into three-dimensional modules (floor and two side walls), with dimensions equal to approximately one room of the house; in some modules other panels are added that delimit the entire room or to obtain others.

This typology is suitable for completing most of the finishes in production: systems, any insulation, painting, floor-coverings, doors and windows; however, it is a very rigid system and requires a repetitive typology of houses.

The investment, for the factory, for the equipment, staff and manpower, is very important. Furthermore it must be considered that the dimensions and weight of the products are considerable (approx. 20 tons), and there could be problems for transport, as well as to have the need for lifting systems both in production (overhead cranes), and on site (mobile cranes) of considerable capacity.

For these reasons is important to build the production site near the same construction site. Then the construction plant can subsequently be disassembled and installed elsewhere, where it is needed. It is almost impossible to find precasters on site that can produce these modules, because special formworks are needed to respect the modularity of the project.

So it is very important that the large initial investment must be supported and guaranteed by continuous production for several years.